The logistics landscape of the mid-2020s has been defined by one word: volatility. If you are an operations leader or a logistics manager, you likely start your day scanning headlines about tariff hikes, labor strikes, or sudden shipping lane closures. The fatigue is real. Rising operational costs and the constant scramble to find capacity have become the “new normal.”

However, a shift is occurring. We are moving from an era of unmitigated disruption to an era of controlled response. This article explores how Supply Chain Chaos Meets Its Match in 2026, detailing the technological maturity, strategic pivots, and operational standards that are finally allowing businesses to tame the unpredictability of global trade.

What Does “Supply Chain Chaos Meets Its Match in 2026” Mean?

To understand why 2026 is a pivotal year, we must first define the concept. “Supply Chain Chaos Meets Its Match” is not a single software or a magic policy. It is the convergence of mature technologies and resilient strategies that neutralize disruption before it cripples operations.

For years, companies have been in “reactive mode”—fighting fires as they appear. In 2026, the industry is transitioning to “predictive control.”

The Three Pillars of the “Match”

The “Match” that defeats chaos is built on three foundational pillars:

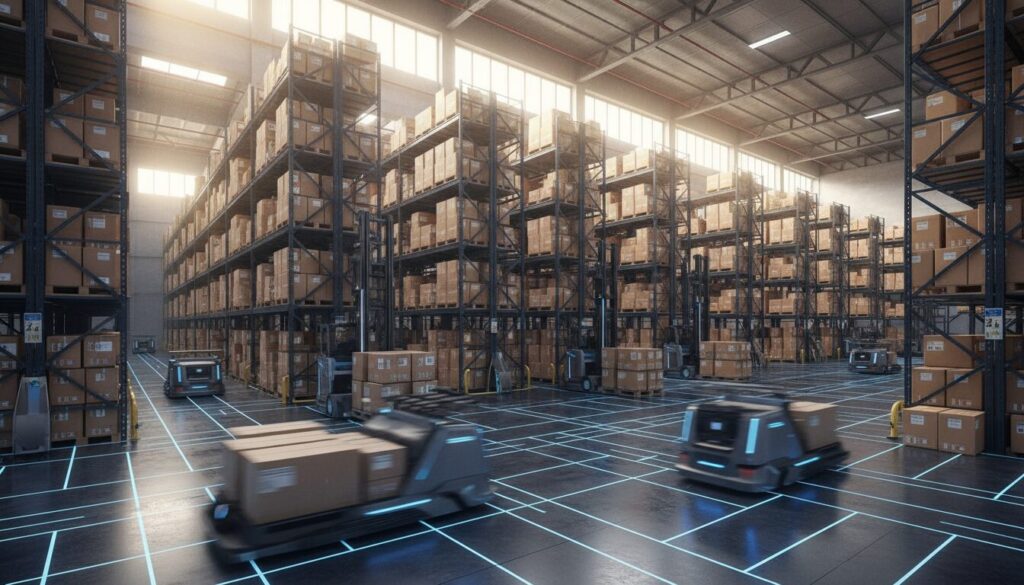

- The End of Pilot Purgatory: Companies are no longer just testing AI and robotics; they are scaling them. As noted in our analysis of the Weekly LogiShift: Dec 29 – Jan 05, logistics is embracing the “Standardization of Complexity,” moving from experimental pilots to full-scale deployment of humanoid robotics and automated systems.

- Geopolitical Resilience: Businesses have stopped hoping for globalization to return to 2019 standards. Instead, they have built “China Plus One” or nearshoring strategies that account for friction.

- Data Unification: The days of siloed Excel sheets are ending. Integrated platforms now provide end-to-end visibility, allowing leaders to see a disruption in a raw material mine and understand its impact on last-mile delivery instantly.

Why Now? The Context of 2026

Why is 2026 the specific turning point? Several global trends have forced this evolution. The chaos hasn’t disappeared—in fact, it has arguably intensified—but our ability to handle it has evolved.

1. The Geopolitical Wall

The trade environment has become increasingly fragmented. For instance, restrictions such as the recent move where China Bans Dual-Use Item Exports to Japan have shaken global markets, impacting everything from rare earths to high-tech components.

In previous years, such a ban might have halted production lines for months. In 2026, mature supply chain leaders have already diversified their sourcing or stockpiled critical inventory based on predictive risk modeling. The chaos is present, but the “match” (strategic redundancy) neutralizes the existential threat.

2. Rate Volatility and Tariff Noise

Financial unpredictability remains a massive pain point. We are currently seeing Transpacific Ocean Rates Spike to Start 2026, driven by Lunar New Year demand and General Rate Increases (GRIs).

Simultaneously, trade friction in North America is high. As discussed in Borderlands Mexico: 2026 Tariff Noise & Resilience Strategy, importers are facing a wall of tariff uncertainty. The difference in 2026 is that companies are utilizing advanced Landed Cost calculation engines and flexible incoterms to mitigate these financial shocks instantly, rather than waiting for the quarterly audit to realize they lost margin.

Benefits of Taming the Chaos

Adopting the tools and strategies that define “Supply Chain Chaos Meets Its Match in 2026” delivers measurable value. It moves logistics from a cost center to a competitive advantage.

Quantitative vs. Qualitative Advantages

The following table outlines the shift organizations experience when they transition from reactive chaos to proactive control.

| Feature | The Chaos Era (2020-2025) | The Match Era (2026+) |

|---|---|---|

| Response Time | Days or Weeks (Reactive) | Minutes or Hours (Predictive) |

| Inventory Strategy | Just-in-Time (Fragile) | Just-in-Case / Hybrid (Resilient) |

| Labor Dependency | High reliance on manual labor | Humanoid & Cobot augmentation |

| Data Visibility | Siloed, delayed reporting | Real-time “Control Tower” view |

| Cost Variance | High (Spot market reliance) | Stabilized (Contract & Index linking) |

1. Cost Stabilization

By utilizing predictive AI for freight procurement, companies can lock in rates before spikes occur. This flattens the curve of operational spend, protecting margins even when ocean rates fluctuate.

2. Workforce Continuity

The “labor shortage” is a chronic issue. However, 2026 sees the rise of the “Humanoid App Store”—a concept where robotic labor is standardized and easily deployed. This ensures that warehouses continue to operate at peak efficiency even during flu seasons or labor disputes.

3. Strategic Agility

When chaos meets its match, decision-making speed increases. If a tariff hits goods from Country A, the system automatically suggests shifting volume to suppliers in Country B, complete with compliance checks and cost implications.

Implementation: How to Master the 2026 Supply Chain

For Operations Leaders, understanding the concept is secondary to executing it. How do you ensure your organization is the one “matching” the chaos rather than being consumed by it?

Here is a roadmap for implementation, aligning with the 5 Supply Chain Management Trends 2026: New Strategy.

Step 1: Audit Your Structural Volatility

Before buying new software, you must understand your vulnerability.

- Supplier Risk: Map your Tier 1, Tier 2, and Tier 3 suppliers. Are they concentrated in geopolitical hot spots?

- Lane Reliance: Are you 100% dependent on the Transpacific Eastbound route?

- Tech Debt: Are your WMS (Warehouse Management System) and ERP (Enterprise Resource Planning) speaking to each other?

Step 2: Embrace the “Standardization of Complexity”

As highlighted in our Weekly LogiShift analysis, the industry is moving toward standardized interfaces for complex tech.

- Action: Don’t build custom software if you can avoid it. Adopt platforms with open APIs that allow you to plug in “best-of-breed” solutions (e.g., a specific AI tool for route optimization connected to a standard SAP or Oracle backbone).

- Action: Look for “Humanoid-ready” warehouse layouts. Even if you don’t use robots today, organize your racking and aisles to be compatible with future automation.

Step 3: Diversify to Counter Geopolitics

Resilience requires options. You cannot let a single government decision halt your business.

- Dual Sourcing: Ensure you have a supplier outside of China for every critical component.

- Nearshoring: For US-based companies, leverage Mexico, but be aware of the “Tariff Noise” mentioned earlier. Use customs brokers who specialize in USMCA compliance to navigate these waters safely.

Step 4: Implement a Digital Twin

A Digital Twin is a virtual replica of your supply chain. It allows you to run simulations.

- Scenario: “What happens if the Suez Canal closes tomorrow?”

- Simulation: The Digital Twin shows you exactly which SKUs will be delayed, the financial impact, and alternative air freight options.

- Result: You make decisions based on data, not panic.

Overcoming Barriers to Adoption

Even with clear benefits, implementing these changes is difficult.

The Cost Barrier

Challenge: Advanced AI and robotics require capital expenditure (CapEx).

Solution: Move to “as-a-Service” models. RaaS (Robotics as a Service) and SaaS (Software as a Service) allow you to treat these upgrades as operating expenses (OpEx), scaling up or down based on demand.

The Talent Gap

Challenge: Your current team may not know how to manage AI agents or humanoid robots.

Solution: Invest in upskilling. The role of a “Logistics Planner” is evolving into a “Supply Chain Data Analyst.” Focus training on data literacy and exception management.

Conclusion: The Choice is Yours

The phrase “Supply Chain Chaos Meets Its Match in 2026” is not a guarantee—it is an opportunity. The chaos of tariffs, bans, and rate spikes is not going away. The structural volatility of the global market is here to stay.

However, the tools to neutralize this chaos are finally mature. By embracing the standardization of complexity, diversifying supply bases to weather geopolitical storms, and adopting predictive technologies, logistics leaders can turn 2026 into a year of stability and growth.

Recommended Next Steps:

- Review your resilience strategy against the 5 Supply Chain Management Trends 2026.

- Conduct a risk audit on your exposure to the China Export Bans.

- Start a pilot program for predictive analytics to handle Ocean Rate Spikes.

Don’t let chaos dictate your year. Make 2026 the year your supply chain fights back.