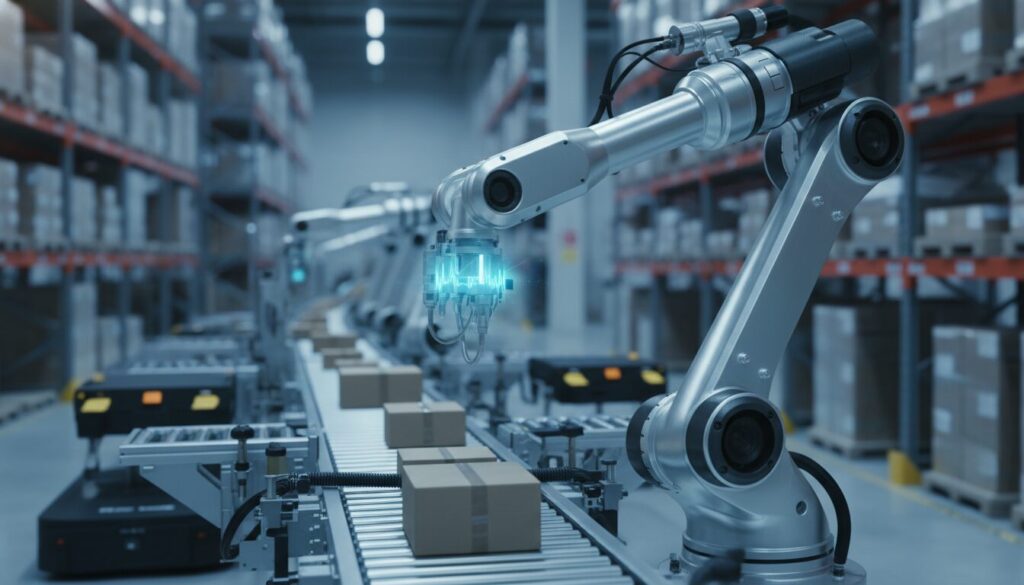

The automated warehouse is no longer a futuristic concept; it is the operational standard for modern logistics. However, as fulfillment centers become increasingly dense with robotics and conveyor systems, a new enemy has emerged: unplanned downtime.

Festo, a global leader in automation technology, has launched AX Motion Insights, an AI-driven predictive maintenance platform that targets this specific pain point. This announcement marks a significant turning point in how the industry approaches maintenance—moving from reactive “fix-it-when-it-breaks” models to proactive, data-driven strategies without the heavy burden of hardware retrofitting.

For logistics executives, this is not just a software update. It is a fundamental shift in how Operational Technology (OT) and Information Technology (IT) converge to protect the bottom line.

Lead: The End of “Run-to-Failure” in Pneumatics

Why does this matter now? Because the “low-hanging fruit” of automation efficiency has already been picked. Warehouses have installed the sorters, the grippers, and the shuttles. The next frontier of efficiency lies in asset utilization—specifically, ensuring that the pneumatics powering these machines do not fail unexpectedly.

Pneumatic systems—the air-driven muscles behind grippers, diverters, and stoppers—are notoriously difficult to monitor. Traditionally, detecting a leaking seal or a sticky valve required a physical inspection or waiting for the machine to jam.

Festo’s AX Motion Insights changes this dynamic by introducing sensor-free anomaly detection. By analyzing existing data patterns rather than requiring thousands of new physical sensors, Festo is lowering the barrier to entry for predictive maintenance. This development aligns closely with the industry’s push for smarter, more resilient infrastructure, as discussed in our previous coverage of robotics trends in IFR Names Top 5 Global Robotics Trends of 2026 for Logistics.

The Facts: Breaking Down AX Motion Insights

Festo’s platform is designed to tackle the specific challenges of high-throughput fulfillment environments. Here is the technical breakdown of the launch:

| Feature | Description | Key Benefit |

|---|---|---|

| AX Motion Insights Pneumatic | AI algorithms that detect anomalies and performance drift in pneumatic components. | Sensor-Free Monitoring: No need to install additional hardware sensors; uses existing PLC/controller data. |

| AX Data Access | A connectivity layer that bridges the gap between Operational Technology (OT) and IT systems. | Unified Data: Correlates motion performance with energy usage and other operational metrics. |

| Smartenance Integration | Direct connection to Festo’s digital maintenance management tool. | Actionable Workflows: Turns an algorithmic “alert” into a specific task for a maintenance technician. |

| Scalable Licensing | A modular pricing model allowing users to purchase only specific functions. | Cost Efficiency: Integrators and machine builders can scale the solution globally without purchasing “bloatware.” |

How It Works Without Sensors

The most disruptive aspect of this technology is its ability to function without additional sensors. In a typical retrofit scenario, adding vibration or pressure sensors to a sorter with 500 pneumatic diverters is cost-prohibitive and technically complex.

AX Motion Insights analyzes the control signals and feedback already present in the system. By learning the “fingerprint” of a healthy cycle, the AI can detect subtle deviations—such as a cylinder taking 50 milliseconds longer to extend due to internal friction or air leakage. This “drift” is identified long before it causes a jam or a full stoppage.

Industry Impact: Who Wins?

The introduction of this platform ripples across three key stakeholders in the logistics ecosystem: the Warehouse Operators, the Machine Builders (OEMs), and the Maintenance Teams.

1. Warehouse Operators and 3PLs

For operators, the primary currency is uptime. A sorter that goes down for 20 minutes during peak season can result in thousands of missed SLAs (Service Level Agreements).

- Impact: By identifying “drift” in pneumatic performance, maintenance can be scheduled during planned breaks rather than interrupting active shifts.

- Energy Savings: Pneumatic leaks are a massive source of wasted energy. By pinpointing leaks early, facilities can significantly reduce compressed air consumption, directly lowering utility bills.

2. Machine Builders and Integrators

OEMs are under pressure to provide machines that are “IoT ready.” However, building custom predictive models for every machine is expensive.

- Impact: The AX Data Access layer and scalable licensing allow OEMs to bundle predictive maintenance as a service. Instead of just selling a machine, they can sell “guaranteed uptime,” creating a recurring revenue stream.

3. Maintenance Crews

The labor shortage in technical maintenance is acute. Finding technicians who can intuitively “hear” a bad valve is becoming impossible.

- Impact: The integration with Smartenance AX bridges the skills gap. The system doesn’t just flash a red light; it sends a specific ticket to a tablet, telling the technician exactly which component is degrading and what to do about it.

For companies looking to quantify these improvements, it is essential to establish a baseline. We recommend reviewing How to Track Before-and-After Automation Metrics in 5 Steps to ensure you are measuring the right KPIs when deploying such solutions.

LogiShift View: The “So What?” for Executives

While the technical specs are impressive, the strategic implication of Festo’s launch is where the real value lies. Here is the LogiShift analysis on the broader market shift.

The Democratization of Predictive Maintenance

Historically, predictive maintenance was a luxury reserved for critical, high-value assets like turbines or massive conveyor drives. Small pneumatic cylinders were considered “consumables”—run them until they break, then replace them.

Festo is proving that in highly automated logistics, there are no small parts. A $50 cylinder failing on a critical divert lane can halt a multimillion-dollar operation. By making monitoring software-based (sensor-free), Festo is democratizing predictive maintenance, making it viable to monitor the “small stuff” that causes the biggest headaches.

The OT/IT Bridge is Finally Crossing the Valley of Death

For years, the industry has talked about Industry 4.0 and the convergence of OT and IT. In practice, it has been a struggle. OT data (pressures, cycle times) is fast and unstructured; IT data (WMS orders) is transactional.

AX Data Access acts as a translator. It allows logistics managers to correlate physical wear with throughput volume.

- Example: You might discover that processing heavy packages (IT data) accelerates pneumatic wear (OT data) by 30%. This insight allows for dynamic maintenance scheduling based on actual throughput rather than arbitrary calendar dates.

Fluid Motion and Soft Automation

This technology also plays a crucial role in the evolution of how robots move. As automation handles more delicate items, the precision of pneumatic force becomes critical. Drifting pressure doesn’t just mean a machine stops; it might mean a gripper crushes a fragile package.

Monitoring these subtleties ensures that the “touch” of the automation remains consistent. For a deeper dive into why motion quality matters, refer to The hidden technology behind fluid robot motion: 2025 Guide.

Takeaway: What Companies Should Do Next

The release of AX Motion Insights is a signal that software is becoming just as important as hardware in the material handling world. Executives should take the following steps:

- Audit Your Pneumatics: Identify the critical choke points in your facility that rely on pneumatics (diverts, sorters, packaging machines). Are these currently monitored?

- Evaluate Data Readiness: Do your current PLCs allow for data extraction? The promise of “sensor-free” monitoring relies on access to control data.

- Rethink Maintenance Contracts: If you are an OEM or Integrator, consider how this technology allows you to offer premium service tiers. If you are an operator, ask your vendors if they are utilizing AI-driven diagnostics.

- Review Integration Capabilities: Ensure that any predictive tool you adopt can speak to your maintenance workforce. A dashboard that no one looks at is useless; a work order sent to a tablet gets done.

Final Thought:

Festo has effectively removed the hardware excuse for lack of visibility. The question is no longer “Can we afford to sensorize every cylinder?” but rather “Can we afford to ignore the data our machines are already generating?”

See also: 5 Steps to Industrialize Humanoids via Siemens PoC Guide for more on how legacy automation giants are paving the way for future tech.