The loading dock is often the most neglected area of warehouse operations. While automated storage and retrieval systems (AS/RS) and high-speed sorters modernize the interior, the dock door remains a bottleneck of manual labor, paper trails, and operational opacity.

For warehouse managers, the journey From Manual to Fully Automated: The Evolution of Loading Dock Workflows is no longer optional—it is a survival mechanism against rising labor costs and detention fees.

This guide outlines a practical, 5-step roadmap to transform your shipping and receiving operations from a chaotic manual process into a streamlined, data-driven automated ecosystem.

The High Cost of the “Manual” Dock

Before discussing the solution, we must quantify the pain. In a traditional manual setup, the loading dock acts as a “black hole” for data.

Operational inefficiencies usually stem from three core areas:

- Yard Blindness: Managers do not know which trucks are arriving or where they are parked, leading to excessive detention fees.

- Manual Handling Risks: Loading and unloading trailers is physically demanding, leading to high injury rates and turnover.

- Data Latency: Paper Bills of Lading (BOL) and manual scanning result in inventory updates lagging behind physical reality by hours.

The solution requires a shift in mindset: stopping the treatment of the dock as a separate entity and integrating it as a digitized node in your supply chain.

The Solution: A Phased Evolution

You cannot jump from clipboards to humanoids overnight. The transition From Manual to Fully Automated requires a phased evolution of loading dock workflows.

This evolution leverages three distinct layers of technology:

- Digital Layer: WMS (Warehouse Management System) and TMS (Transportation Management System) integration.

- Vision Layer: AI cameras and sensors for real-time tracking.

- Physical Layer: AMRs (Autonomous Mobile Robots), automated conveyors, and eventually, humanoid robotics.

The Technology Stack

| Component | Function | Status |

|---|---|---|

| WMS/TMS | The Brain: Manages orders and schedules. | Essential |

| AI Vision | The Eyes: Tracks trucks, pallets, and safety. | transformative |

| AMRs/AGVs | The Legs: Moves goods from dock to storage. | Growing |

| Humanoids | The Hands: Handles complex, unstructured loading. | Emerging |

Process: 5 Steps to Fully Automated Dock Workflows

Follow this step-by-step framework to modernize your operations.

Step 1: Digitize the Documentation (The Foundation)

Automation fails without clean data. The first step is eliminating paper.

- Implement Advanced Shipping Notices (ASN): Require suppliers to send digital ASNs. This allows your WMS to know exactly what is arriving before the truck opens its doors.

- Digital BOLs: Switch to e-signatures and digital Bills of Lading. Drivers should check in via mobile apps or kiosks, not paper forms.

Action: Audit your current paper usage. If a forklift driver has to stop to sign a paper, that is your first automation target.

Step 2: Implement AI Vision for Yard Visibility

Once data is digital, you need real-time visibility of physical assets. “Yard blindness” is a primary cause of bottlenecks.

By installing AI-enabled cameras at the gate and dock doors, you can automate check-ins and dock assignments.

- License Plate Recognition (LPR): Automatically logs truck arrival times.

- Door Utilization: Sensors detect if a truck is at the bay and if the door is open.

As discussed in our previous guide, AI Vision Systems: Transform Yard & Warehouse Ops Guide, these systems can reduce detention fees by accurately timestamping every movement, eliminating disputes with carriers.

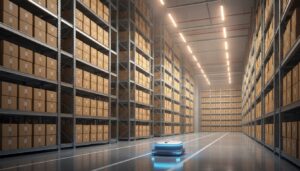

Step 3: Automate Material Movement (Dock-to-Stock)

The next phase moves inside the facility. Moving pallets from the dock staging area to the storage buffer is low-value travel time for human operators.

- Deployment: distinct lanes for Autonomous Mobile Robots (AMRs) or Automated Guided Vehicles (AGVs).

- Workflow:

- Manual operator or telescopic conveyor unloads the trailer.

- Pallet is placed in a “handshake zone.”

- AMR picks up the pallet and transports it to the AS/RS induction point or bulk storage.

This separates the “loading” task from the “transport” task, doubling the efficiency of your dock personnel.

Step 4: Address the “Last Inch” with Smart Robotics

The hardest part of dock automation is entering the trailer. Trailers are unstructured, messy environments.

Option A: Telescopic Conveyors

For loose-loaded cartons (floor loaded), extendable conveyors are the standard. They bring the belt to the worker, reducing walking but still requiring manual lifting.

Option B: Smart Palletizing Arms

For palletized goods, collaborative robots (cobots) are changing the game. As highlighted in UR, Robotiq & Siemens: The AI Shift in Smart Palletizing, new AI-driven systems allow robots to handle variable pallet patterns without complex reprogramming. This shifts the workflow from “lifting” to “supervising.”

Option C: The Future – Humanoid Logistics

For truly unstructured environments, the industry is moving toward general-purpose humanoids. Unlike fixed arms, these robots can walk into trailers and handle diverse SKUs.

While this may seem futuristic, leading companies are already running Proof of Concepts (PoCs). For a practical roadmap on this technology, refer to 5 Steps to Industrialize Humanoids via Siemens PoC Guide.

Step 5: Orchestrate via WES (Warehouse Execution System)

The final step is connecting the Digital (Step 1), Vision (Step 2), and Physical (Steps 3 & 4) layers.

A Warehouse Execution System (WES) acts as the conductor. It does not just record data (like a WMS); it directs work.

- Scenario:

- Vision system sees Truck A arrive.

- WES triggers the dock door to open and assigns AMR Fleet to Dock 4.

- WES alerts the Palletizing Robot to prepare for SKU Type X based on the ASN.

- The entire process occurs with zero human data entry.

Results: Expected Improvements

Transforming from manual to fully automated workflows yields measurable ROI. Below is a comparison of key metrics.

| Metric | Manual Operations | Automated Operations | Improvement |

|---|---|---|---|

| Truck Turnaround Time | 2 – 4 Hours | < 45 Minutes | 75% Faster |

| Data Accuracy | 92% (Human Error) | 99.9% (Systematic) | Eliminated Claims |

| Detention Fees | High / Monthly Expense | Near Zero | Cost Reduction |

| Labor Dependency | High (Heavy Lifting) | Low (Supervisory) | Staff Stability |

Case Context: The Safety Factor

Beyond speed, automation solves the safety crisis. Forklifts near pedestrian dock workers account for a significant percentage of warehouse accidents. By utilizing AMRs and automated loading systems, you physically separate humans from heavy machinery.

Summary: Keys to Success

The evolution From Manual to Fully Automated: The Evolution of Loading Dock Workflows is a journey of integration, not just acquisition.

To succeed, remember these three keys:

- Data First: Do not buy robots until your ASNs and WMS data are 100% accurate. Robots cannot guess.

- Solve Visibility: You cannot automate what you cannot see. Use AI vision to digitize the physical environment first.

- Scale the Physical: Start with AMRs for transport, then move to automated loading as technology like humanoids matures.

The loading dock is the handshake between your warehouse and the world. By automating it, you ensure that handshake is firm, fast, and error-free.

See also: