The era of rigid, monolithic warehouse automation is facing its most significant challenge yet. The recent announcement that Mytra has secured a massive $120M Series C funding round—bringing its total capital raised to over $200M—is not just a financial headline; it is a validation of “software-defined” infrastructure in the heavy logistics sector.

For decades, automating pallet movement meant committing to massive steel structures, cranes, and fixed paths—a high-stakes game of Tetris that, once built, could rarely be changed. Mytra is betting that the future of material handling looks less like construction and more like cloud computing. With strategic backing from industry giants like RyderVentures and Lineage, this funding signals a pivot toward systems that abstract physical movement into programmable primitives.

For executives watching the labor gap widen and real estate costs soar, the Mytra announcement offers a glimpse into a future where the warehouse floor is as flexible as the software that runs it.

The Facts: Unpacking the Mytra Funding

While the headline numbers are impressive, the specifics of the deal reveal the strategic direction of the industry. Mytra’s approach targets the most cumbersome unit of measure in the warehouse: the heavy pallet.

Here is the breakdown of the development:

Mytra Series C Funding Overview

| Category | Detail |

|---|---|

| Funding Amount | $120M Series C (Total raised exceeds $200M) |

| Key Investors | Greenoaks (Lead), RyderVentures, Lineage, Eclipse |

| Core Technology | Software-defined Automated Storage and Retrieval System (ASRS) |

| Target Load | Heavy pallets up to 1,360 kg (approx. 3,000 lbs) |

| Key Metrics | 32% labor reduction; 34% improvement in storage density |

| Strategic Goal | To solve the projected 2 million industrial labor gap by 2030 |

What Makes This Different?

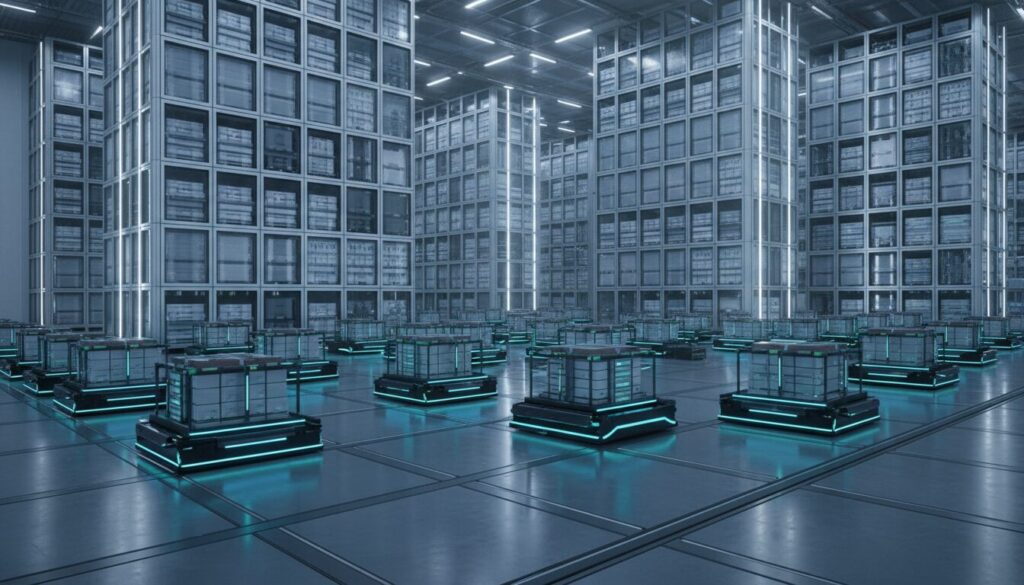

Unlike traditional Autonomous Mobile Robots (AMRs) that travel on the floor, or traditional ASRS that require massive custom racking, Mytra uses a lightweight grid structure. The bots move in three dimensions, capable of climbing and traversing the grid to retrieve heavy pallets.

However, the hardware is secondary to the philosophy. Mytra markets its solution as converting material flow into “programmable primitives”—specifically Move, Store, and Pick. By abstracting these functions, Mytra attempts to do for logistics what AWS did for servers: create a flexible, scalable resource that can be spun up or down without re-architecting the entire facility.

Industry Impact: Beyond the Hype

The injection of capital into Mytra has ripple effects across the supply chain ecosystem. It suggests that the market is ready to move past point solutions (robots that just move from A to B) toward infrastructure-level transformation.

1. For Warehouses and Distribution Centers

The immediate impact is on “Dead Space” and labor dependency. Traditional warehouses suffer from poor vertical utilization because standard forklifts and reach trucks have limits. Traditional crane-based ASRS solves this but is prohibitively expensive and rigid for many brownfield sites.

Mytra’s claim of 34% higher storage density allows warehouses to delay moving to larger facilities. Furthermore, the 32% labor reduction is critical. As noted in our guide, Automation — A Strategic Growth Enabler: The Ultimate Guide, automation is no longer just about cost-cutting; it is a survival mechanism against the labor shortage. Mytra provides a way to automate heavy tasks that previously required skilled forklift operators—a role that is increasingly hard to fill.

2. For 3PLs and Carriers

The involvement of Ryder and Lineage is telling. Third-Party Logistics providers (3PLs) operate on thin margins and short contracts. They have historically been hesitant to invest in heavy automation because they cannot risk sinking millions into a facility for a client that might leave in three years.

Mytra’s modular nature changes the ROI calculation. If the system is “software-defined” and modular, it reduces the risk of sunk costs. 3PLs can deploy this technology to win contracts and potentially redeploy or reconfigure it as client needs change.

3. The “Brownfield” Revolution

The greatest barrier to ASRS adoption has been the facility itself. Most existing warehouses were not built with the reinforced floors or super-flat requirements of traditional automation in mind. Mytra’s system is designed to be lighter and more adaptable, making high-density automation accessible to the thousands of aging warehouses across North America and Europe that cannot support heavy crane infrastructure.

See also: Rapid Robotics: Alps Logistics’ 5-Week Warehouse Revolution for more on how rapid deployment is becoming a key competitive advantage.

LogiShift View: The Abstraction of Material Flow

The most profound aspect of Mytra’s rise isn’t the robot; it’s the methodology. We are witnessing a shift from Task-Specific Automation to Software-Defined Logistics.

In the past, if you bought a palletizer, it palletized. If you bought a conveyor, it conveyed. These were hardware assets with a single function. Mytra represents a shift where the hardware is a generic “muscle,” and the software defines the operation.

The “Cloud” Analogy

Mytra explicitly compares its approach to cloud computing. In the cloud, you don’t worry about which specific server processes your request; you just ask for compute power. In Mytra’s vision, a warehouse manager shouldn’t worry about which forklift goes to which aisle. They simply request a pallet, and the system resolves the physical pathing.

This mirrors the trends we discussed in UR, Robotiq & Siemens: The AI Shift in Smart Palletizing, where AI and software are taking precedence over mechanical capability. The intelligence is moving from the operator’s head to the system’s core.

The Competitor Landscape

This funding positions Mytra to compete with established heavyweights differently.

- Vs. AutoStore: AutoStore dominates the small-item bin picking market. Mytra is effectively trying to become the “AutoStore for heavy pallets.” If they succeed, they unlock a market segment AutoStore cannot touch (1,000kg+ loads).

- Vs. AMRs: AMRs are flexible but suffer from traffic congestion and low vertical storage. Mytra utilizes verticality (3D movement) to beat AMRs on density.

For a comparison of high-density storage tech, see: Boozt & Cognibotics: Advanced AutoStore Automation.

The “So What?” for Executives

The funding implies that capital markets believe the future of warehousing is high-density and labor-light. If your 5-year strategy relies on hiring more forklift drivers and leasing more square footage, you are betting against the trend. The capital efficiency of software-defined storage—where you can squeeze 30% more product into the same building—will make traditional sprawling warehouses economically unviable.

Takeaway: What Companies Should Do Next

The Mytra announcement is a signal to re-evaluate your automation roadmap. The distinction between “flexible AMRs” and “rigid ASRS” is blurring.

Here are three immediate actions for logistics leaders:

- Audit Your “Dead Space”: Measure the vertical utilization of your current pallet storage. If you are below 60% utilization due to forklift limitations, systems like Mytra are now a viable retrofit option.

- Revisit RFPs for Heavy Material Handling: If you are currently evaluating ASRS, pause. Ensure you are not locking yourself into “monolithic” infrastructure. Ask vendors about modularity and re-configurability.

- Focus on Software Integration: As hardware becomes more generic and flexible, the competitive advantage lies in data accuracy. A software-defined system fails if the inventory data is corrupt. Ensure your WMS data hygiene is impeccable.

See also: 5 Steps to Scale Accuracy Without Rebuilding Operations to prepare your data for this level of automation.

Mytra’s $120M raise is a milestone. It proves that the industry is hungry for a solution that handles the heavy lifting of traditional logistics with the agility of modern software. The future of the warehouse is dense, vertical, and programmable.