The “Honeymoon Phase” Trap in Warehouse Automation

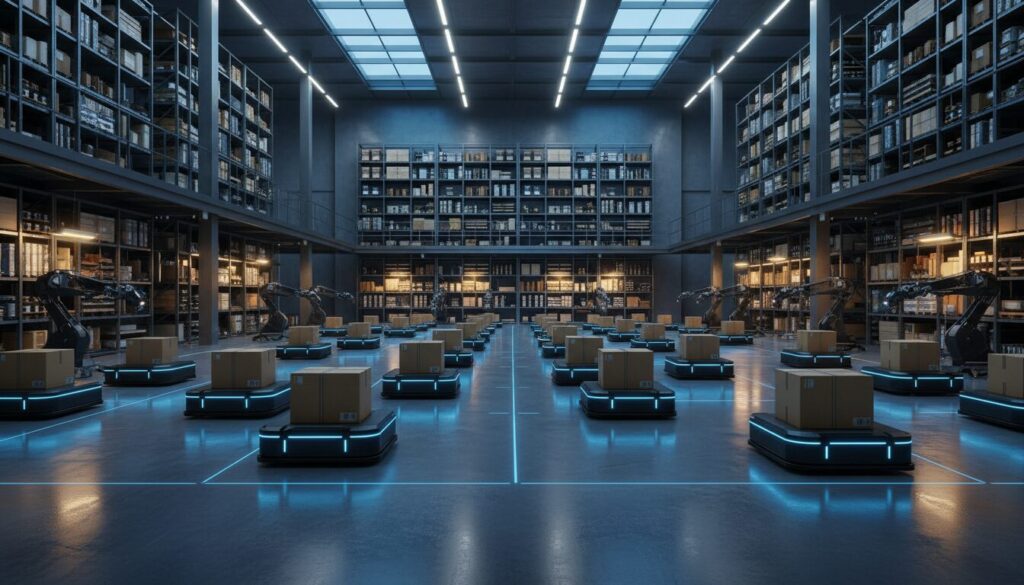

You have just completed a six-month implementation of a new Automated Mobile Robot (AMR) system or a conveyor sortation upgrade. The system is live. The lights are blinking, the robots are moving, and the warehouse floor looks futuristic.

Then, the CFO walks onto the floor and asks a simple question: “Are we actually saving money yet?”

Most warehouse managers instinctively answer “Yes,” pointing to the reduction in temporary labor or the speed of the robots. But when the monthly P&L statement arrives, the numbers tell a confusing story. Total operating costs might have remained flat, or worse, increased due to maintenance contracts and software licensing fees.

This is the common operational pain of Confirmation Bias.

We want the automation to work, so we look for data that supports that conclusion (like “picking speed”) while ignoring data that contradicts it (like “downtime” or “exceptions handling”). Without a rigorous framework for Before-and-After Automation Metrics, you are flying blind. You cannot distinguish between genuine efficiency gains and simple shifts in workload.

As discussed in our Best Logistics Outcome Solutions 2025: Beyond AI Hype Guide, the industry is moving away from buying technology for technology’s sake. The focus is now entirely on outcomes.

This guide provides a specific, step-by-step method to measure those outcomes accurately, ensuring you compare results without fooling yourself.

Solution: The “Normalized Baseline” Technique

The core problem with most before-and-after comparisons is that the warehouse environment is never static. Comparing “October (Manual)” to “November (Automated)” is often a recipe for disaster because SKU mix, order volume, and labor availability change daily.

The solution is the Normalized Baseline Technique.

This involves three specific actions:

- Sanitizing Historical Data: Removing outliers from your “Before” data to create a realistic baseline.

- Defining Proxy Metrics: Measuring total system throughput, not just the speed of the machine.

- Volume Normalization: Adjusting post-automation results to match pre-automation volume scenarios (or vice versa) to create an “apples-to-apples” comparison.

This method reveals the truth behind the hype. It aligns with the principles found in Automation — A Strategic Growth Enabler: The Ultimate Guide, where we emphasize that automation must be measured by its contribution to strategic growth, not just tactical speed.

Process: Implementing the 5-Step Measurement Framework

To effectively use Before-and-After Automation Metrics, follow this rigid 5-step process. Do not skip the data cleaning phase.

Step 1: Clean Your Historical Data (The “Before”)

Most managers take the “Average Units Per Hour (UPH)” from the previous year and use that as the baseline. This is dangerous. An average hides the peaks and valleys that determine your labor planning.

Action Items:

- Segment by Process: Do not lump “Warehousing” into one metric. Isolate “Picking,” “Packing,” and “Replenishment.”

- Remove Outliers: Exclude days with massive IT outages or “Black Friday” volume spikes from the baseline average (unless the automation is specifically for peak).

- Audit Error Rates: Manual operations often have hidden costs in returns. If you don’t calculate the cost of errors in the “Before” stage, the “After” stage will look artificially expensive (because automation requires precision).

See also: 5 Steps to Scale Accuracy Without Rebuilding Operations for details on establishing accuracy baselines.

Step 2: Establish “Total Cost” Metrics

Do not measure “Pick Rate” alone. A robot might pick faster, but if it requires two humans to fix its jams or organize its inventory, you haven’t saved anything. You need composite metrics.

Recommended Metrics Table:

| Metric Name | Formula | Why it Matters |

|---|---|---|

| fully Loaded Cost Per Unit (CPU) | (Total Labor $ + Maintenance $ + Software License $) / Total Units Shipped | Captures the hidden costs of automation (licenses/maintenance) vs. pure labor. |

| Throughput Efficiency | Total Units Processed / (Direct Labor Hours + Indirect Support Hours) | Prevents hiding labor in “support” roles to make the robots look efficient. |

| Order Cycle Time | Time from “Order Drop” to “Carrier Scan” | Measures speed from the customer’s perspective, not just the machine’s speed. |

| Perfect Order Rate | % of orders on time, in full, damage-free, with correct docs | Automation often improves accuracy; this metric captures that value. |

Step 3: The Stabilization Period (The “Dip”)

When you flip the switch, productivity will likely drop. This is the “J-Curve” of implementation. Comparing the first month of automation to your historical best will lead to panic.

The Rule:

- Define a “Stabilization Period” (typically 4-8 weeks).

- During this time, track Technical Availability (uptime) and User Adoption (login rates, override rates).

- Do not calculate ROI during this period. Focus on training and debugging.

Step 4: Normalize for Volume and Mix

This is where you stop “fooling yourself.”

If your volume drops by 20% the month you go live, your Cost Per Unit might skyrocket because the fixed costs of automation (depreciation, software) are spread over fewer units. Conversely, if volume spikes, efficiency looks artificially high.

How to Normalize:

- Calculate the Variable Cost per Unit and Fixed Cost per Month for both systems.

- Project what the “Manual System” would have cost at the current new volume.

- Compare the Actual Automated Cost vs. the Projected Manual Cost.

Calculation Example:

- Scenario: Volume increased by 30% post-automation.

- Wrong Comparison: Comparing last year’s total payroll to this year’s total payroll. (Costs went up, so automation looks like a failure).

- Right Comparison: Calculate how many overtime hours and temp staff would have been required to handle this +30% volume manually. Compare that hypothetical cost against your actual current spend.

Step 5: Factor in “Soft” Gains

Automation often solves problems that don’t show up immediately on a spreadsheet, such as labor scarcity or safety.

- Turnover Rate: Has staff retention improved because the work is less physically demanding?

- Space Utilization: Did the automation allow you to delay moving to a larger facility?

- Planning Agility: Are you able to react to order drops faster?

For more on planning efficiency, refer to Eliminate Warehouse Waste with AI Planning.

Results: What Success Looks Like

When you apply this rigorous Before-and-After Automation Metrics framework, the picture becomes clear. You move from “guessing” to “knowing.”

Below is a case study example of a warehouse that moved from RF Picking to Autonomous Mobile Robots (AMR), applying these measurement principles.

The “Before” vs. “After” Comparison

Context: Mid-sized e-commerce fulfillment center. 30% volume increase year-over-year.

| Metric | Before (Manual RF) | After (AMR Assist) | Improvement (Real) |

|---|---|---|---|

| Average Pick Rate | 65 Lines/Hour | 140 Lines/Hour | +115% (Raw Speed) |

| Indirect Labor Ratio | 10% (Supervisors) | 18% (Robot Wranglers/Techs) | -8% (Process degradation) |

| Accuracy Rate | 99.1% | 99.9% | +0.8% (Significant cost saving) |

| Cost Per Unit (Normalized) | $1.45 | $1.12 | 22% Cost Reduction |

| Training Time | 3 Days | 4 Hours | 83% Faster Onboarding |

Analysis of Results

- The Trap: Looking only at “Pick Rate,” one might assume a 115% gain in total productivity.

- The Reality: Indirect labor increased (someone has to manage the robots), and software costs were added.

- The Verdict: The true ROI is a 22% reduction in Cost Per Unit, driven heavily by the ability to handle increased volume without adding proportional headcount.

This level of granular detail allows the Planning Team to adjust shifts and workflows accurately. For insights on building such a team, watch: Setting Up a Zero-Error Supply Chain Planning Team.

Summary: Keys to Success

Comparing results without fooling yourself requires intellectual honesty and data discipline.

1. Define “Success” Before You Buy

Don’t wait until the system is installed to decide what metrics matter. Set the baseline before the vendor signs the contract.

2. Isolate Variables

Don’t blame the automation for a bad inventory mix, and don’t credit the automation for a seasonal dip in difficult orders. Normalize your data.

3. Measure “Total System” Health

High speed with high error rates is not an improvement; it is simply “accelerated waste.” Always pair throughput metrics with accuracy metrics.

4. Continuous Re-evaluation

Automation is not “set it and forget it.” Processes drift. Re-run your Before-and-After Automation Metrics quarterly to ensure the system is still delivering value as your business profile changes.

By strictly adhering to these metrics, you transform automation from a shiny toy into a verified financial engine for your logistics operations.