In the modern logistics landscape, the phrase “do more with less” has shifted from a management mantra to an absolute necessity. Operations leaders are squeezed between two opposing forces: the skyrocketing demand for rapid, accurate fulfillment and the crushing weight of rising operational costs and labor shortages.

If you are a logistics manager or executive, you are likely losing sleep over these questions:

- How do we handle peak season volume without burning out our staff?

- How can we maintain margins when wages and real estate costs are climbing?

- Is our current manual infrastructure holding us back from scaling?

The solution lies in shifting your perspective. It is time to stop viewing technology merely as a capital expense and start recognizing Automation — A Strategic Growth Enabler. This guide will walk you through how automation transforms logistics from a cost center into a competitive advantage, drawing on real-world examples and actionable strategies.

What is Automation — A Strategic Growth Enabler?

To understand Automation — A Strategic Growth Enabler, we must first decouple the concept of automation from simple “mechanization.”

Historically, automation meant replacing a human arm with a robot arm to do the same repetitive task. While this improved speed, it was a tactical fix, not a strategic one.

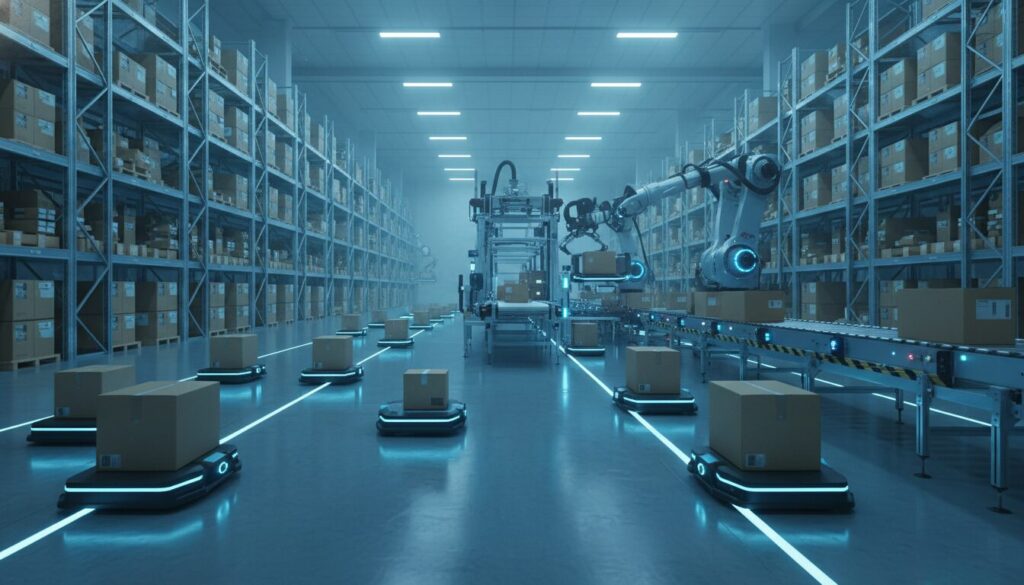

Strategic Automation goes further. It is the holistic integration of hardware (robots, conveyors) and software (AI, WMS) to optimize entire workflows, not just individual tasks. It enables growth because it decouples revenue generation from headcount. In a manual warehouse, doubling your output usually requires doubling your staff. With strategic automation, you can double your output with only a marginal increase in resources.

The Ecosystem of Strategic Automation

Automation as a growth enabler typically consists of three layers:

- Physical Automation: Autonomous Mobile Robots (AMRs), Automated Storage and Retrieval Systems (AS/RS), and sortation systems.

- Process Automation: Robotic Process Automation (RPA) for invoicing, data entry, and scheduling.

- Intelligence Layer: Artificial Intelligence (AI) and Machine Learning (ML) that predict demand and optimize routes.

See also: Automate Warehouse Ops: Lessons from C.H. Robinson’s AI — Learn how AI is helping leaders reclaim 40% of their time by automating administrative burdens.

Why Now? The Urgency of Adoption

Why is Automation — A Strategic Growth Enabler trending specifically now? The logistics industry is currently undergoing a “perfect storm” of disruption. Waiting to automate is no longer a safe option; it is a risk to business continuity.

1. The Labor Crisis and Demographic Shifts

In many developed nations, the working-age population is shrinking. Logistics is often viewed as “3D” work (Dirty, Dull, Dangerous), making recruitment difficult. Automation is the only viable bridge across this talent gap.

Recent pilots, such as the deployment of humanoid robots in manufacturing plants, show that we are moving from R&D to commercial necessity. The goal isn’t to replace humans, but to fill roles that humans can no longer fill.

See also: Boston Dynamics’ Atlas Pilot: The Humanoid Logistics Shift

2. The “Amazon Effect” on Customer Expectations

Consumers and B2B clients now expect next-day or same-day delivery with near-perfect accuracy. Manual picking methods often hit a ceiling of efficiency (typically 60-100 units per hour). To meet modern throughput demands, automation is required to push these numbers to 300+ units per hour.

3. Agility and Rapid Deployment

In the past, automation meant bolting heavy machinery to the floor for 10 years. Today, solutions are flexible. “Robotics as a Service” (RaaS) and modular systems allow warehouses to deploy automation in weeks, not years.

For example, Alps Logistics successfully deployed a specialized automated warehouse system in just five weeks, proving that agility is now a core feature of automation.

See also: Rapid Robotics: Alps Logistics’ 5-Week Warehouse Revolution

Quantitative and Qualitative Benefits

When pitching Automation — A Strategic Growth Enabler to stakeholders, it is crucial to present a balanced view of both hard numbers and soft benefits.

Quantitative Advantages ( The ROI)

| Benefit Category | Impact Description | Estimated Improvement |

|---|---|---|

| Throughput | Faster picking and sorting speeds compared to manual carts. | 2x – 5x Increase |

| Accuracy | Reduction in picking errors (mis-picks), reducing reverse logistics costs. | 99.9% Accuracy |

| Space Utilization | High-density AS/RS systems utilize vertical space, reducing real estate footprint. | 40% – 60% Space Saved |

| Labor Costs | Reduction in overtime pay and temporary labor during peaks. | 20% – 30% Reduction |

Companies like Boozt have utilized advanced AutoStore automation to solve picking bottlenecks, redefining what is possible regarding warehouse efficiency.

See also: Boozt & Cognibotics: Advanced AutoStore Automation

Qualitative Advantages (The Strategic Value)

- Scalability: When a sudden spike in demand occurs (e.g., Black Friday), automated systems can run 24/7 without fatigue. You cannot ask a human workforce to work three shifts back-to-back without severe consequences; robots can do so effortlessly.

- Employee Satisfaction & Retention: By offloading the heavy lifting and walking (sometimes 10+ miles a day) to robots, human workers can focus on value-added tasks like quality control or problem-solving. This reduces injury rates and improves morale.

- Data Visibility: Automated systems generate data with every movement. This provides granular insights into inventory flow, allowing for better decision-making.

Implementation: How to Enable Growth

Adopting Automation — A Strategic Growth Enabler is a journey. Many projects fail not because the technology is bad, but because the implementation strategy is flawed.

Here are the critical steps to ensure your automation initiative drives actual growth.

Step 1: Operational Assessment & Simplification

Before you automate, you must optimize. Automating a bad process only makes the bad process faster.

Analyze your current SKUs, order profiles, and bottlenecks. Are your processes standardized?

- Action: Clean up your data and standardize workflows.

- Insight: You don’t always need to rebuild everything from scratch. Sometimes, small procedural changes pave the way for automation.

See also: 5 Steps to Scale Accuracy Without Rebuilding Operations

Step 2: Define “Growth” Metrics

What does growth mean for you? Is it handling 20% more volume with the same staff? Is it expanding into a smaller urban warehouse?

Define clear KPIs:

- Cost Per Unit (CPU)

- Orders Per Man Hour (OPMH)

- Order Cycle Time

Step 3: Start Small (The Pilot Approach)

Avoid the “Big Bang” implementation where you try to automate the entire facility overnight.

- Target a Zone: Automate just the picking of “Class A” fast-movers, or perhaps the transport of pallets from receiving to staging.

- Test and Learn: Use modular solutions (like AMRs) that can be scaled up easily. If five robots work well, adding five more is simple.

Step 4: Integration is Key

Your automation hardware must talk to your Warehouse Management System (WMS).

- Ensure your WMS has open APIs or verified integrations with the robotics vendor.

- Data silos will kill efficiency. If the robot knows where the item is, but the WMS doesn’t update the inventory in real-time, you will create stock discrepancies.

Step 5: Change Management

Automation is often feared by staff as a “job killer.”

- Communication: Frame automation as a tool to help them, not replace them.

- Upskilling: Train your best warehouse associates to become “Robot Operators” or “System Super Users.” This provides a career path and secures buy-in.

Overcoming Common Barriers

Even with the promise of growth, obstacles exist. Here is how to navigate them.

The CAPEX Barrier

Challenge: “We don’t have $5 million for an AutoStore.”

Solution: Look into RaaS (Robotics as a Service). This shifts the cost from Capital Expenditure (CAPEX) to Operating Expenditure (OPEX). You pay a monthly fee for the robots, similar to a subscription, drastically lowering the barrier to entry.

The Complexity Barrier

Challenge: “We don’t have engineers to maintain robots.”

Solution: Choose vendors that offer “managed services.” Modern robotics providers often include 24/7 remote monitoring and maintenance in their contracts.

The Flexibility Barrier

Challenge: “Our business changes every year; we can’t be locked in.”

Solution: Avoid bolting steel to the floor if your business is volatile. Opt for AMRs (Autonomous Mobile Robots) that use LiDAR to navigate. If you move warehouses, the robots can move with you.

Conclusion: The Next Step in Your Growth Journey

Automation — A Strategic Growth Enabler is not just industry jargon; it is the dividing line between logistics operations that will thrive in the next decade and those that will struggle to survive.

By integrating automation, you are not just cutting costs. You are building an infrastructure that is resilient to labor shortages, capable of meeting aggressive customer demands, and ready to scale instantly as your business grows.

Key Takeaways:

- Shift Mindset: View automation as a growth engine, not just a cost-cutter.

- Start Agile: Look for flexible solutions like AMRs or modular storage systems.

- Focus on Data: Ensure your underlying processes and data are clean before applying technology.

- Empower People: Use automation to elevate your workforce, not just replace them.

The technology is ready. The market is demanding it. The only question remaining is: Are you ready to enable your growth?

Recommended Next Step:

Review your current operational bottlenecks. Identify the one task that consumes the most labor hours with the least strategic value (e.g., walking time or manual data entry). Investigate a pilot automation program specifically for that task.

For more insights on optimizing your logistics operations, explore our case studies on Alps Logistics and C.H. Robinson.