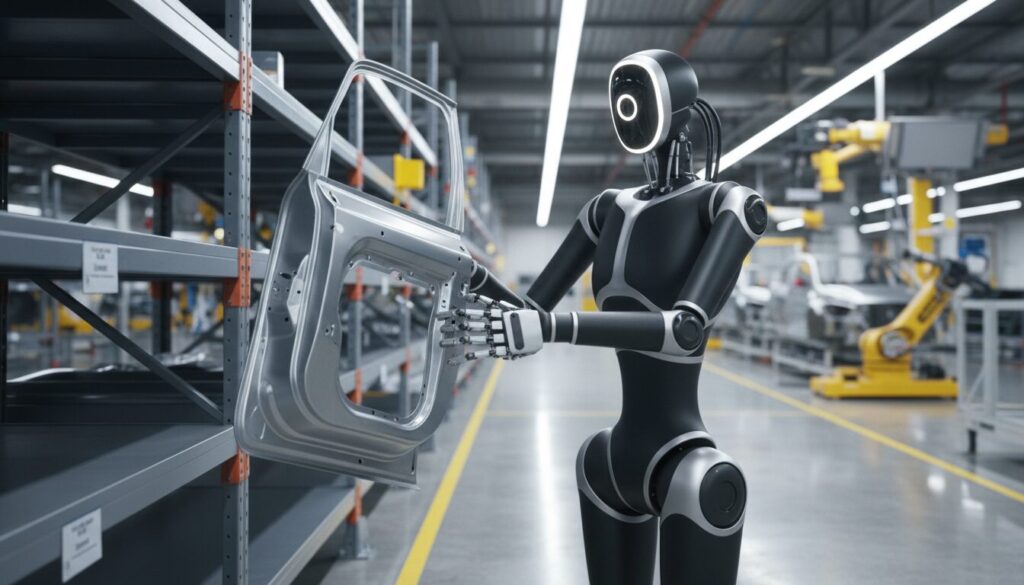

The era of the viral, backflipping robot is over. The era of the factory worker has begun.

For years, logistics executives have viewed humanoid robotics as a spectacle—impressive engineering with questionable return on investment (ROI). However, the recent deployment of Boston Dynamics’ fully electric Atlas robot at a Hyundai automotive plant in Georgia signals a definitive shift from R&D curiosity to commercial necessity. This is no longer a concept video; it is a live pilot in a high-volume production environment.

With Goldman Sachs projecting the humanoid robot market to reach $38 billion by 2035, and Hyundai announcing plans to deploy “tens of thousands” of these units, the supply chain sector is witnessing the dawn of General Purpose Humanoids (GPH). For logistics leaders, understanding this transition is critical not just for future-proofing operations, but for surviving the escalating labor crisis.

The Facts: Atlas Goes to Work

The deployment at the Hyundai Motor Group Metaplant America (HMGMA) in Georgia represents a significant milestone in industrial automation. Unlike previous iterations of Atlas, which were hydraulically powered and largely experimental, the new electric Atlas is designed specifically for commercial scalability.

The robot has been tasked with autonomously moving automotive parts—specifically transferring heavy shock absorbers from storage containers to line-sequencing flows. This is a task traditionally reserved for human workers due to the dexterity and irregular grasping required.

Operational Snapshot

The following table summarizes the key operational details of this pilot program:

| Category | Details |

|---|---|

| Robot Model | Boston Dynamics “Electric Atlas” (fully motorized, no hydraulics) |

| Location | Hyundai Motor Group Metaplant America, Georgia, USA |

| Primary Task | Autonomous sorting and sequencing of automotive parts (e.g., shock absorbers) |

| Operation Mode | Fully autonomous execution with cognitive computer vision |

| Training Method | Sim-to-Real Reinforcement Learning (VR teleoperation creates training data) |

| Scale Strategy | Hyundai plans to deploy “tens of thousands” of units across manufacturing and logistics |

| Market Context | Boston Dynamics CEO Robert Playter cites urgent competition from state-funded Chinese startups |

The Technology Behind the Pilot

The critical differentiator in this pilot is the training methodology. Boston Dynamics is utilizing a “Sim-to-Real” approach. Instead of programming every movement manually, operators use a VR headset to control the robot remotely (teleoperation) for a short period.

This human-guided session generates data that is fed into simulation software. In a digital twin environment, thousands of virtual robots practice the task simultaneously. Reports indicate that a single teleoperation session can be multiplied to train 4,000 virtual robots in just six hours. This drastically reduces the deployment time from months to days, making the technology viable for dynamic warehouse environments where SKUs and workflows change frequently.

Industry Impact: The Ripple Effect

The introduction of bipedal humanoids into a live automotive supply chain affects more than just the manufacturing floor. It signals a restructuring of how logistics facilities will be designed and staffed.

Impact on Warehousing and Distribution Centers

The most immediate impact is on “Brownfield” automation. Traditional automation (AS/RS, conveyor belts) requires purpose-built facilities (“Greenfield”) or massive infrastructure overhauls.

- Infrastructure Agnostic: Atlas is designed to operate in environments built for humans. It can navigate narrow aisles, step over debris, and reach shelves that wheeled autonomous mobile robots (AMRs) cannot.

- Vertical Utilization: Unlike flat-bed AMRs that only move goods horizontally, humanoids utilize vertical space, picking items from varying heights without requiring specialized racking systems.

- Workflow Continuity: In the Hyundai pilot, Atlas handles parts that are irregular in shape (shock absorbers). This dexterity allows warehouses to automate the handling of non-conveyable items, which currently account for a significant portion of labor costs.

Impact on Shippers and 3PLs

For Third-Party Logistics (3PL) providers and large shippers, this technology introduces a new metric for competitive advantage: Fleet Scalability.

- Peak Season Elasticity: Humanoid robots offer a solution to the seasonal labor crunch. Instead of hiring and training temporary workers for Q4 peaks—a process fraught with turnover and safety risks—companies could lease humanoid fleets that require zero training time once the software model is established.

- Standardization of Output: Robots do not fatigue. The deployment of Atlas ensures that the throughput at hour 12 is identical to hour 1. For Just-In-Time (JIT) manufacturing environments like Hyundai’s, this consistency is invaluable for preventing line stoppages.

Impact on the Labor Market

While the narrative often drifts toward job displacement, the current industry reality is a labor shortage.

- Gap Filling: With millions of unfilled manufacturing and logistics jobs globally, Atlas is positioned to fill roles that humans increasingly refuse—tasks that are dull, dirty, and dangerous.

- Role Evolution: The workforce will shift toward “Robot Guardians” or fleet managers. The skill set required on the warehouse floor will transition from manual lifting to basic troubleshooting and flow management.

LogiShift View: The “So What?”

Beyond the headlines, there are three critical nuances in this development that logistics executives must recognize.

1. The Death of the “Perfect Environment” Requirement

For decades, robots required perfection: flat floors, precise lighting, and safety cages. The electric Atlas pilot proves that robotics is moving into “unstructured environments.” The robot uses cognitive AI to perceive changes in real-time—if a shock absorber is slightly askew, it adjusts.

The Insight: You no longer need to rebuild your warehouse to automate it. The barrier to entry for advanced automation has dropped from “New Building CapEx” to “Equipment Leasing OpEx.”

2. The Data Flywheel and the Chinese Threat

Boston Dynamics is not operating in a vacuum. CEO Robert Playter explicitly mentioned the competitive pressure from Chinese startups, many of which are aggressively state-funded. This geopolitical tech race benefits the consumer.

The Insight: We are entering a period of rapid price deflation for humanoid hardware. As Boston Dynamics competes with companies like Unitree and Fourier Intelligence, the cost per unit will plummet. The “tens of thousands” of units Hyundai plans to buy will likely drive the unit cost down to parity with the 2-year cost of a human FTE (Full-Time Equivalent) sooner than analysts expect—likely within 3 to 5 years.

3. Simulation is the New Onboarding

The ability to train 4,000 virtual robots in six hours via simulation is the game-changer. In traditional logistics, changing a workflow (e.g., from kitting automotive parts to packing e-commerce orders) required weeks of reprogramming.

The Insight: “Switchover cost” is vanishing. A humanoid robot can be sorting auto parts in the morning and palletizing boxes in the afternoon, provided the simulation models exist. This creates the first truly “General Purpose” automation asset in logistics history.

Takeaway: What Companies Should Do Next

The commercial pilot of Atlas at Hyundai is a signal that the technology is ready for early adoption. Executives should take the following steps to prepare:

-

Audit Your “Brownfield” Limitations:

Identify areas in your current warehouses where automation was previously rejected due to infrastructure costs (e.g., mezzanines, narrow aisles, uneven floors). These are now prime candidates for humanoid pilots. -

Quantify “Dexterous Waste”:

Analyze your labor spend specifically on tasks that require human hands (manipulating irregular objects, bin picking). This is your potential ROI baseline for humanoid adoption. -

Prepare IT Infrastructure for “Embodied AI”:

These robots are essentially data centers on legs. They require robust industrial Wi-Fi (or private 5G), low-latency edge computing, and integration with WMS/WES. Ensure your digital backbone can support high-bandwidth video uplinks for teleoperation and diagnostics. -

Monitor the “Robot-as-a-Service” (RaaS) Market:

Do not plan to buy these robots outright immediately. Look for RaaS models that allow you to pilot the technology with lower financial risk. Boston Dynamics and its competitors will likely offer leasing structures akin to forklifts.

The Bottom Line: The electric Atlas at Hyundai is not an experiment; it is a preview of the standard operating procedure for 2030. The question is no longer if humanoids will enter the supply chain, but how quickly your competitors will deploy them.