The logistics industry is currently facing a “perfect storm” of challenges. Fuel costs are fluctuating wildly, consumer demands for next-day delivery are intensifying, and a chronic labor shortage is squeezing margins tight.

For years, the industry’s holy grail was Supply Chain Visibility. The goal was simple: “Where is my shipment?” Logistics managers invested millions in track-and-trace software, GPS devices, and IoT sensors. While knowing the location of goods is critical, it is no longer enough. Knowing a shipment is stuck at a port doesn’t solve the problem; it merely highlights it.

This is where the paradigm shifts. We are moving into an era described by the phrase: Beyond Visibility: AI Redefines Logistics.

This article is designed for logistics professionals and operations leaders who are tired of reacting to problems and are ready to prevent them. We will explore how Artificial Intelligence (AI) is transforming supply chains from passive observation to active, autonomous decision-making, ensuring you stay competitive in a volatile market.

What is “Beyond Visibility: AI Redefines Logistics”?

To understand this concept, we must first distinguish between “Visibility” and “Intelligence.”

From Passive Tracking to Active Orchestration

Visibility is the ability to track inventory and shipments in real-time. It answers the questions: Where is it? and When will it arrive? It is essentially a status report.

Beyond Visibility implies taking that data and applying Artificial Intelligence (AI) to make decisions. It answers more complex questions:

- What will happen if this shipment is delayed?

- How can we reroute to avoid the incoming storm?

- How much inventory should we order based on next month’s predicted trends?

In short, “Beyond Visibility: AI Redefines Logistics” means shifting from a reactive supply chain (fixing problems after they happen) to a predictive and prescriptive supply chain (stopping problems before they occur).

The Four Stages of Logistics Maturity

To visualize where AI fits in, consider the four stages of supply chain analytics:

- Descriptive (Visibility): What happened? (e.g., “The truck was late.”)

- Diagnostic: Why did it happen? (e.g., “There was traffic.”)

- Predictive (AI): What will happen? (e.g., “Weather patterns suggest the truck will be late tomorrow.”)

- Prescriptive (AI + Automation): What should we do? (e.g., “Automatically re-route the truck to an alternative path to save 2 hours.”)

Moving “Beyond Visibility” means operating in stages 3 and 4.

Why Now? The Urgency of AI Adoption

Why is the concept of “Beyond Visibility: AI Redefines Logistics” trending right now? Several global factors are converging to make AI not just a luxury, but a necessity.

1. Unprecedented Supply Chain Complexity

Global trade networks have become incredibly intricate. A single delay in a component factory in Asia can halt production lines in Europe and North America. Human planners can no longer manually calculate the ripple effects of these disruptions in real-time. AI thrives on this complexity, analyzing millions of data points instantly to suggest the best course of action.

2. The Data Explosion

Modern supply chains generate massive amounts of data:

- IoT sensor readings (temperature, shock, humidity).

- Telematics from trucks.

- Market demand signals.

- Weather forecasts.

Without AI, this is just “noise.” AI processes this Big Data to find patterns that humans would miss, turning raw data into actionable insights.

3. The Rise of Generative AI (GenAI)

The emergence of GenAI (like ChatGPT but for industry) has lowered the barrier to entry. Logistics managers can now query their systems using natural language (e.g., “Show me all high-risk shipments for next week and suggest alternative carriers”). This democratization of data access is accelerating the shift beyond simple visibility.

Key Benefits of AI-Driven Logistics

Adopting an AI-first approach offers tangible, quantitative benefits. It moves logistics from a cost center to a competitive advantage.

Quantitative Improvements

- Cost Reduction: AI algorithms optimize delivery routes (reducing fuel consumption by 10-20%) and optimize container loads (reducing wasted space).

- Inventory Optimization: Predictive analytics reduces safety stock requirements by accurately forecasting demand, freeing up working capital.

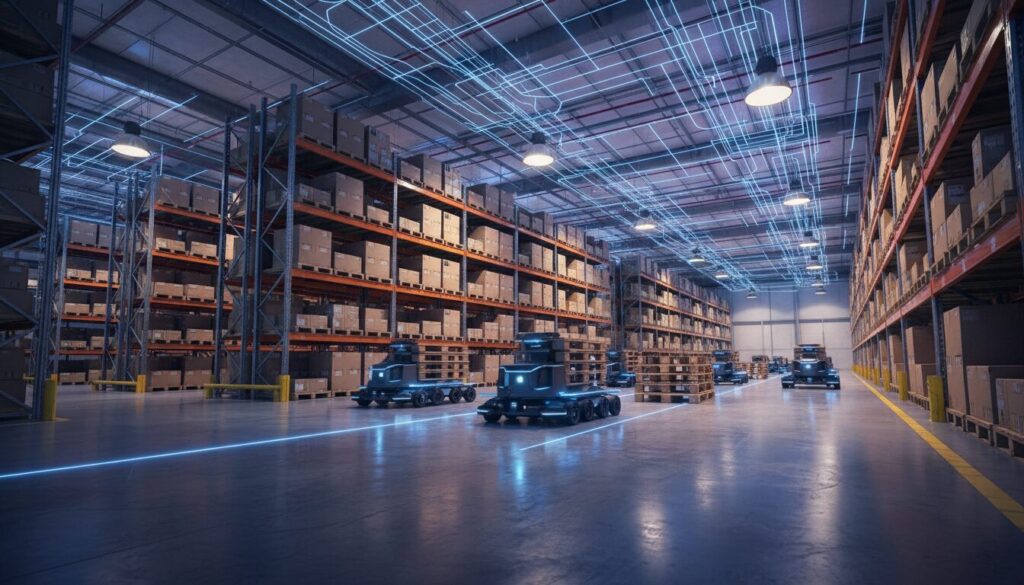

- Labor Efficiency: In warehouses, AI-driven robots and cobots handle repetitive tasks, allowing human workers to focus on value-added activities.

Qualitative Advantages

- Agility and Resilience: When a disruption occurs (e.g., a port strike), AI models can simulate different scenarios (Digital Twins) and recommend the best contingency plan within seconds.

- Customer Satisfaction: By predicting delays before they happen, companies can proactively communicate with customers or expedite shipments, maintaining trust.

Comparison: Traditional vs. AI-Enhanced Logistics

The following table illustrates the operational differences when you move beyond visibility.

| Feature | Traditional Logistics (Visibility) | AI Logistics (Beyond Visibility) |

|---|---|---|

| Focus | Monitoring status | Optimizing outcomes |

| Response Time | Reactive (after delay) | Proactive (before delay) |

| Data Usage | Siloed, historical reports | Integrated, real-time predictive |

| Decision Making | Manual, experience-based | Automated, data-driven |

| Maintenance | Scheduled (preventive) | Predictive (based on wear/tear) |

Core Technologies Driving the Change

To fully grasp how Beyond Visibility: AI Redefines Logistics, it is helpful to look at the specific technologies involved.

Predictive Analytics

This uses historical data and statistical algorithms to identify the likelihood of future outcomes.

- Use Case: Predicting a spike in demand for winter coats in a specific region based on long-term weather forecasts, allowing for pre-positioning of stock.

Computer Vision

AI-powered cameras can “see” and interpret images.

- Use Case: Automated quality control on conveyor belts, or drone-based inventory counting in warehouses, which is significantly faster and more accurate than manual counting.

Natural Language Processing (NLP)

NLP allows computers to understand and process human language.

- Use Case: Automating back-office operations by reading emails, processing invoices, and updating the ERP system without human intervention.

Implementation: How to Move Beyond Visibility

For operations leaders, the transition to AI can seem daunting. However, a strategic, phased approach ensures success.

1. Cleanse Your Data

AI is only as good as the data it is fed. If your ERP, WMS (Warehouse Management System), and TMS (Transportation Management System) contain duplicate, outdated, or erroneous data, the AI will make bad decisions.

- Action: Conduct a comprehensive data audit before investing in AI tools.

2. Break Down Silos

“Beyond Visibility” requires holistic data. If your procurement team doesn’t share data with your logistics team, AI cannot optimize the end-to-end chain.

- Action: Implement a Control Tower architecture that integrates data streams from all departments and external partners.

3. Start with a “Pilot” Project

Do not try to overhaul your entire supply chain overnight. Choose a specific pain point to prove ROI.

- Examples:

- Implement an AI route planner for last-mile delivery.

- Use a demand forecasting tool for a single product category.

4. Focus on Human-AI Collaboration

AI does not replace the logistics professional; it augments them. The goal is “Human-in-the-loop” operations.

- Strategy: Train your workforce to interpret AI recommendations. The AI provides the data-driven suggestion, but the human manager makes the final strategic call based on nuance and relationships.

The Role of Change Management

Implementing AI is 20% technology and 80% culture. Employees may fear job loss or find new systems difficult. Clear communication about how “Beyond Visibility: AI Redefines Logistics” empowers them—by removing tedious manual tracking tasks—is essential for adoption.

Conclusion

The logistics industry is at an inflection point. The era of simply watching dots on a map is fading. Beyond Visibility: AI Redefines Logistics is not just a catchy slogan; it is the new operating standard for efficient, resilient supply chains.

By leveraging AI, companies can stop fighting fires and start preventing them. The shift from reactive visibility to proactive intelligence enables:

- Lower operational costs.

- Higher service levels.

- Greater resilience against global disruptions.

Recommended Next Steps:

- Assess: Evaluate your current “Visibility” maturity. Do you have the data needed for AI?

- Educate: Share this article with your team to align on the definition of “Beyond Visibility.”

- Partner: Look for technology partners who offer predictive capabilities, not just tracking dashboards.

The future of logistics is not just about seeing the road ahead; it is about knowing exactly how to navigate it before you even turn the key. Embrace the AI revolution, and redefine what is possible in your supply chain.